Rotary Screw Air Compressor

V SERIES

Technical Parameter

V Series Oil Cooled Permanent Magnet VSD Screw Air Compressor(Direct Drive)

| Model |

Max Working Pressure |

F.A.D |

Motor Power |

Connection |

Net Weight |

Dimension (L*W*H) |

| bar |

psig |

m³/min |

CFM |

hp |

kw |

kgs |

mm |

| AS15-7V |

7 |

102 |

2,5 |

88 |

20 |

15 |

G1" |

280 |

1050*600*1125 |

| AS15-8V |

8 |

116 |

2.6 |

91 |

| AS15-10V |

10 |

145 |

2.0 |

70 |

| AS22-7V |

7 |

102 |

3.8 |

134 |

30 |

22 |

G1" |

295 |

1050*600*1125 |

| AS22-8V |

8 |

116 |

3.6 |

127 |

| AS22-10V |

10 |

145 |

3.0 |

106 |

| AS37-7V |

7 |

102 |

6.7 |

236 |

50 |

37 |

G1-1/2" |

425 |

1200*650*1500 |

| AS37-8V |

8 |

116 |

6.5 |

229 |

| AS22-10V |

10 |

145 |

5.4 |

190 |

| AS55-7V |

7 |

102 |

10.2 |

360 |

75 |

55 |

G2" |

860 |

1580*1160*1600 |

| AS55-8V |

8 |

116 |

10.0 |

353 |

| AS55-10V |

10 |

145 |

8.0 |

282 |

| AS75-7V |

7 |

102 |

13.2 |

466 |

100 |

75 |

G2" |

930 |

1580*1160*1600 |

| AS75-8V |

8 |

116 |

12.5 |

441 |

| AS75-10V |

10 |

145 |

10.0 |

353 |

-

According to the standard of GB19153-2009

-

Standard power supply: 380v/50Hz/3Ph

-

Compressor stage: one stage compression

-

Exhaust temperature: ambient temperature +15°C

-

Please contact us for any specification that is not within the above mentioned stardards.

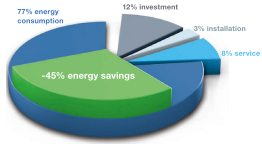

Why Energy Efficience ?

Energy costs represent about 77% of the total operating cost of your compressor. That is Why efficiently reducing the energy consumption of your compressed air installation should be a major focus.

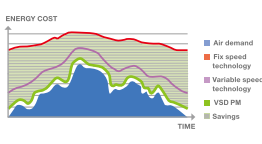

Why VSD (variable speed)?

As a majority of customers have a variable demand for compressed air, a variable speed compressor is superior VS a fixed speed compressor in terms of energy saving by perfectly matching air supply to air demand of avoiding unloading losses.

Why PM (permanent magnet motor)?

Permanent magnet is a high efficiency motor combines our variable speed technology with our new and highly efficient drive train, resulting in energy savings of up to 40%

Oil Cooled Motor VS Air Cooled Motor

Newly Oil Cooled Motor

- IE5 super high efficiency oil cooled motor Temperature resistance can reach to 180°C

- Ip65 motor protection level, suit for heavy duty factory (runs every 24 hours)

- No fan blade, wind resistance loss is 0.

- Even in low speed, the motor cooling volume is not changed. More reliable and longer service life.

- Lower noise because of the motor case is wrapped by the oil.

Traditional Air Cooled Motor

- IE4 high efficiency air cooled motor

- Temperature resistance is 140°C

- IP23 or IP54 motor protection level can be chosen

- Wider adjust speed, torque suit for wider frequency setting

Newly oil cooled motor VS Traditional oil cooled motor

Newly Oil Cooled Motor

- Mould forming for the newly motor, no welding point, leakage risk.

- Small pressure difference because of the rotary oil passage.

- The cooling oil goes by arc shape, make sure the oil can be cooling uniformity.

- Easy for checking or repair

Traditional oil cooled motor

- Need welding at the end and face of the oil passage,it will have the trachoma, deformation and oil leakage risks.

- Higher pressure difference, because of the small oil passage and the reciprocating oil way

- Square oil passage,the oil can not flow in the corner,that will make the corner in higher temperature.

- Internal oil passage, it's not easy to check or repair.